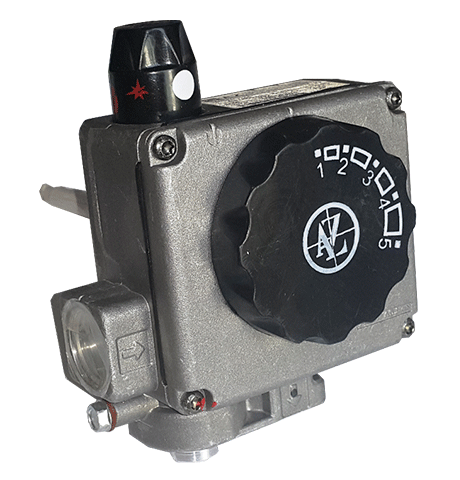

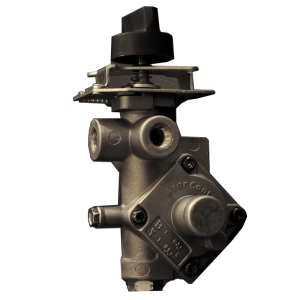

Technical Specs of AZ3

- Adjusters

- Thermostat adjustment

- Thermostat adjustment will be carried out In the gas control valve manufacturing company where any change or re-adjustment should be done by the experts.

- Adjustment of gas flow to the pilot burner

- Take out the black plastic safety cap Z.

To increase and reduce the gas flow rate, turn the PlLOT ADJ screw counter clockwise and clockwise, respectivly. - Adjustment of gas outlet pressure

- Take out the thermostat knob and take the red plastic safety cap (L.P.G.).

- When the liquid gas (L.P.G.) is applied, turn the NO P.R screw clockwise to the end, then take the regulator out and fully screw in the PILOT ADJ and NO P.R screws.

- When the natural gas (N.G.) is applied, turn the NO P.R screw counter clockwise; to increase or reduce gas outlet pressure, turn the PR ADJ screw clockwise or counter clockwise, respectively.

- Safety Automatic shut- down system in overheat Temperatures (E.C.O.Device)

- In case of thermostat’s non-efficiency, the automatic shut- down system (E.C.O.) will prevent water temperature increase (prior to boiling) to give more safety.

- Automatic shut-down eyetem le connected with thermocouple’e electric current circuit In eerlee and will be activated when warm water temper-tun increases (more than E.c.o. operating. refine).

- Then the electric current will be cut off and the ceding device (E) will block the passage of an flow to the main and pilot burners.

Technical Spec

| Maximum Working Pressure | 50 mbar(500mmH2O) |

| Maximum Working Temperature (Valve Body) | 80 C |

| Maximum Working Temperature (thermocouple) | 600 C |

| response time with normal thermocouple heated to 600 C | on 5-10 s |

| off 30-45 s | |

| Pressure Governor Range | 3-18 mbar |

| 15-30 mbar (no request) | |

| Delta P at 2.5 mbar | N.G 2.4 m3/h |

| L.P.G 3.0 kg/h | |

| Range of Adjustment for the Temperature control | N.G 30-70 C |

| L.P.G 35-75 C | |

| Operating temperature for the temperature limiting switch | 85±5 |

| weight | 800 gr |